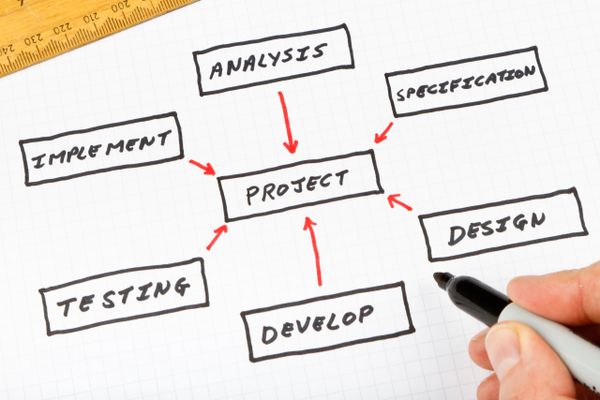

Project Management Partner (PMP)

Core Objective

Value Proposition

Value Proposition

Project Management Partner (PMP) :

- Zero-defect products leaving production.

- On-time delivery for clients.

- Seamless coordination between production, quality, and logistics teams.

Value Proposition

Value Proposition

Value Proposition

- “We own the defects so you don’t have to.”

- “On-time, every time – quality guaranteed.”

- “Seamless bridge between production and customers.

Report Features

Value Proposition

Key Responsibilities

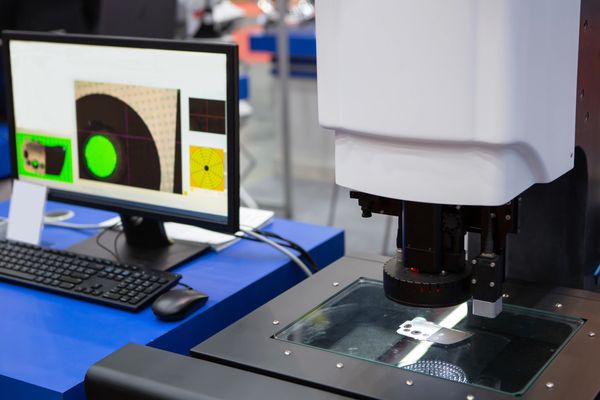

- Dashboard Interface – Defect reports, timelines, and delivery status.

- Analytics & Reports – Automated weekly/monthly defect & dispatch analysis.

- Ticketing System – For defects raised and resolved with timestamps.

- Communication Hub – Integrated chat/call system for production & QC.

- Client Premises Visit – Clients Premises Visit in case of requirement

Key Responsibilities

Continuous Improvement & Risk Management

Key Responsibilities

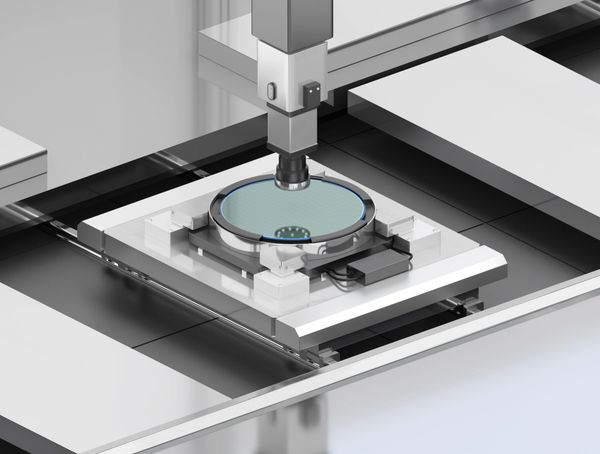

Defect Monitoring & Accountability

- Implement a defect tracking dashboard.

- Root cause analysis for each defect and preventive action plan.

- Direct reporting to management on defect percentages and cost implications.

Timely Dispatch Management

- Create production-dispatch timelines.

- Track material movement using real-time status updates.

- Send alerts for delays to stakeholders.

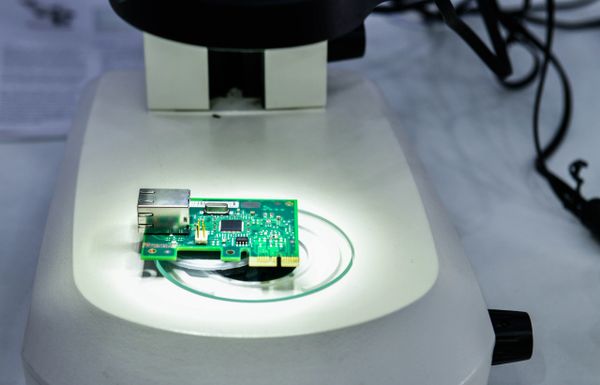

Production Coordination

- Daily production-progress meetings.

- Digital approval system for quality checks before dispatch.

- QC-based demand forecasting for raw materials & resources.

Manpower for Project Management

Continuous Improvement & Risk Management

Continuous Improvement & Risk Management

Our third-party project management team is powered by experienced professionals dedicated to ensuring zero-defect quality and on-time deliveries. We bring together cross-functional expertise to manage every stage of the production-to-dispatch process effectively

1) Project Manager

2)Quality Assurance (QA) Specialists

3)Production Coordinators

4)Logistics & Dispatch Executives

5)Data Analysts & IT Support

Continuous Improvement & Risk Management

Continuous Improvement & Risk Management

Continuous Improvement & Risk Management

- Conduct root cause analysis for delays or defects and implement preventive actions.

- Track key performance indicators (KPIs) like defect rate, on-time dispatch %, and rework cost.

- Suggest process improvements to reduce production delays and quality risks.

- Maintain compliance with industry standards and client-specific requirements

Torsam Automation Private Limited

180, Sector 9, Faridabad-121006 Haryana, India

Office Landline :- 0129-4167158

Copyright © 2019-2025 Torsam Automation - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.